Submitted by L. Millard on Mon, 18/10/2021 - 10:56

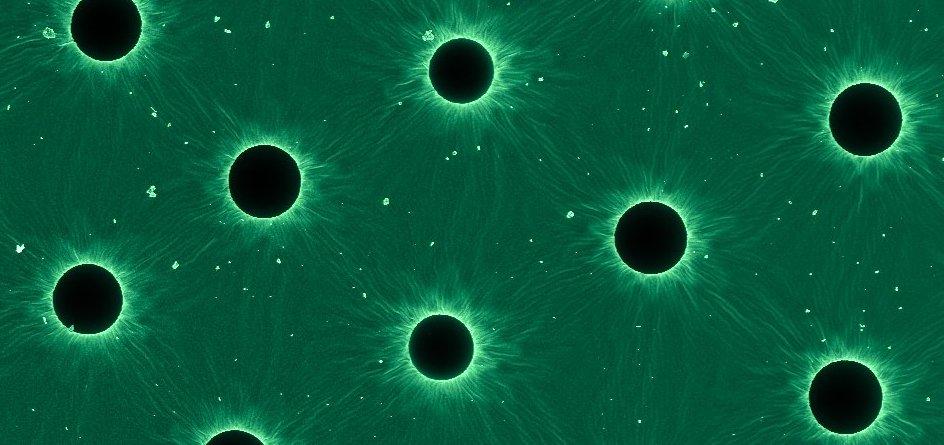

A research collaboration with IRC engineers has marked a first by demonstrating the digital inkjet printing and self-organisation of microdroplets on fluid surfaces to create structures of functional materials.

The Fluids in Advanced Manufacturing research group, including Dr Qingxin Zhang and the IRC’s Dr Ronan Daly and Dr Niamh Willis-Fox, are exploring using the drops as microscale test tubes for reactions. They hope that the millions of drops, capable of fitting on a small area, can be used to accelerate drug discovery reactions. The Department of Engineering has published a full article about the research which can be viewed here.

We have also enabled a shift towards safer, more environmentally responsible manufacturing of these structures. The result is a low-cost and customisable technique that has become dramatically more repeatable and tuneable, and one which paves the way for rapid translation to applications in combination drug delivery and drug discovery techniques Dr Ronan Daly

A paper titled ‘Capturing the value in printed pharmaceuticals – A study of inkjet droplets released from a polymer matrix’, published by the International Journal of Pharmaceuticals, presents the results of the study that “shows there is a robust approach to maintaining multiple formulations within a polymer matrix, each delivered in its own carrier fluid or excipient. It also indicates that there is a significant sensitivity to interfacial energies but that with a tuned formulation, using low levels of surfactants or other stabilising ingredients, it will be possible to deliver repeatable drug release.”

The research, which is being progressed by the team in work funded by the BBSRC – Biotechnology and Biological Sciences Research Council – will also explore the use of capturing and releasing the droplets for tailored treatment of wounds. Working closely with the BBSRC Impact Acceleration Account and University of Cambridge spin-out, LIFNanoRx Limited, which uses quantum biology to capture the healing properties of the stem cell growth factor ‘LIF’, the team envisage printed products with the potential value to transform wound healing.

The IRC’s Dr Su Metcalfe, CEO of LIFNanoRx, said: “The combined powers of printed personalised delivery together with the quantum biology of biomimetics, bring a new era of sustainable and universal therapeutics at low cost and high value.”

Dr Ronan Daly, said: “We have also enabled a shift towards safer, more environmentally responsible manufacturing of these structures. The result is a low-cost and customisable technique that has become dramatically more repeatable and tuneable, and one which paves the way for rapid translation to applications in combination drug delivery and drug discovery techniques.”

Related links:

Qingxin Zhang; Niamh Willis-Fox; Clare Conboy; Ronan Daly. ‘Direct-writing microporous polymer architectures – print, capture and release’. Materials Horizons (2021). DOI: 10.1039/d0mh01460e

Qingxin Zhang; Niamh Willis-Fox; Ronan Daly. ‘Capturing the value in printed pharmaceuticals – A study of inkjet droplets released from a polymer matrix’. International Journal of Pharmaceutics (2021). DOI: 10.1016/j.ijpharm.2021.120436